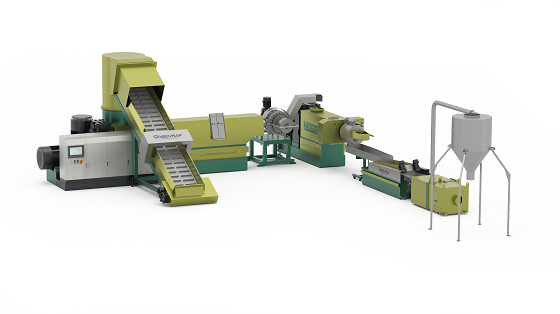

GREENMAX Recycling Extrusion Machinery

The plastic recycling extrusion machinery is a one-step, effective, and sustainable solution for recycling a variety of plastic materials. The end product of the compactor recycling system remains in pellet form and can be used straight in blown film, pipe extrusion, and injection molding production. This removes the demand for added processing steps, helping manufacturers save time and money.

What is a Plastic Recycling Extrusion Machinery?

A Plastic Recycling Extrusion Machinery is a one-step recycling system that incorporates compacting, plasticizing, and pelletising features. It is suitable for recycling and pelletising plastic film, foam, bags, woven bags, and frothing materials.

How does it work?

A Plastic Recycling Extrusion Machinery works by first crushing plastic waste into tiny flakes. The flakes are then compacted and heated in the compactor area to thaw the plastic and get rid of contaminations. The molten plastic is after that fed into the pelletizer, which cuts it into pellets.

Plastic Recycling Extrusion Machinery Pelletized Products can be used in a variety of applications, including:

Blown film

Tube extrusion

Injection molding

Other plastic processing applications

Trustworthy Partner of Integrated Plastic Recycling Extrusion Machinery

GREENMAX follow Industry 4.0 smart manufacturing trends and use an intelligent PLC control system with a user-friendly HMI interface, which greatly increases the automation level. We also use digital program logic technology and ECO inverter modules to create fully automatic pelletising systems, to meet the growing demand for recycling.

Recycling plastic waste through a plastic recycling extrusion machinery and converting it into high-quality pellets that can be used for a variety of purposes helps reduce the impact of plastic waste on the environment.

|

If you'd like to find out more or get professional plastic recycling advice, get in touch with the GREENMAX team! |

- Rigid Plastic Pelletizing Machine The G-Rigid Plastic recycling pelletizing machine is suitable for reprocessing pre-crushed plastic regrinds, efficiently converting them into high-quality pellets.

- EPE Pelletiser Machine EPE granulator machine is the waste EPE foam through crushing - melting - pumping - cooling - granulation and other processes, the final product into pellets.